Client Name:

SeeBridge EU Funded Program and IMMIB. Istanbul Mineral and Material Exporter Association

Service Category:

Energy Management Platform Development

Project Date:

2024-2025

Project Objective:

Design and implement an advanced energy management system for plant and utility-scale operations that fully integrates Carbon Adjustment (CBAM) considerations.

Projects Activities:

- Simulation Platform Development: Create an advanced simulation platform to model energy usage, forecast carbon emissions (including CBAM considerations), and evaluate various efficiency improvement strategies.

- Process Optimization: Implement targeted process improvements to enhance operational efficiency, reduce energy waste, and minimize carbon emissions.

- Expert Mentoring: Provide personalized one-on-one mentoring to guide businesses through digital and green transitions, ensuring the adoption of best practices in energy management and sustainability.

- Industry Engagement: Actively participate in industry events, workshops, and conferences focused on green energy, CBAM, and digital transformation to stay updated on emerging trends and regulatory requirements.

- Strategic Partnerships: Develop and nurture partnerships with industry peers and institutions to foster collaborative innovation in sustainability and energy management.

- Field Participation: Allocate resources for travel and attendance at key events to gain in-depth insights, enhance networking opportunities, and capture cutting-edge industry knowledge.

- Capacity Building: Invest in comprehensive training and professional development programs to build a skilled workforce capable of implementing advanced energy management solutions and sustainable practices.

Client Name:

Creativa, Egypt Digital Innovation Hub

Service Category:

Develop training Program in CubeSat and Computer Vision Applications

Project Date:

2025

Project Objective:

The CubeSat and Computer Vision Applications training course explores the integration of computer vision techniques in CubeSat missions for space-based imaging, object detection, and data analysis. Participants will gain hands-on experience in deploying AI-driven vision systems for Earth observation and autonomous satellite operations.

Projects Activities:

- Needs Assessment and Curriculum Design: Conducting in-depth research to identify industry demands and designing an inclusive, EQF Level 3-aligned curriculum focused on AI-driven computer vision applications for CubeSat missions.

- Content Development and Platform Implementation: Creating interactive multimedia learning materials and setting up a user-friendly online platform with hands-on simulations and accessibility features.

- Quality Assurance and Content Finalization: Engaging subject matter experts for rigorous content validation, ensuring technical accuracy, clarity, and alignment with industry standards.

- Program Launch and Learner Recruitment: Deploying targeted outreach strategies to attract a diverse pool of learners, including underrepresented groups in space technology and AI.

- Training Delivery and Continuous Support: Providing live Q&A sessions, discussion forums, and personalized guidance to enhance learner engagement and practical understanding.

- Assessment and Certification: Evaluating participant performance through practical projects and exams, offering feedback, and awarding certificates upon successful completion.

- Impact Analysis and Project Management: Assessing the training’s effectiveness through data-driven insights while ensuring efficient execution, risk mitigation, and long-term sustainability.

Client Name:

EIT Deep tech

Service Category:

Develop training Program in AI-Powered Cybersecurity Field

Project Date:

2024-2025

Project Objective:

AI-Powered Cybersecurity Training program is to equip the European workforce with advanced AI-driven cybersecurity skills, enhancing digital resilience and promoting a diverse, inclusive talent pool. The program with in partnership with OctaInsight-Norway and Kiev Academic University-Ukraine.

Projects Activities:

- Needs Assessment and Curriculum Design: Conducting comprehensive research to identify industry needs and developing an inclusive, EQF Level 3-aligned curriculum for AI-powered cybersecurity training.

- Content Development and Platform Implementation: Creating engaging multimedia learning materials and establishing a user-friendly online platform with interactive features and accessibility accommodations.

- Quality Assurance and Content Finalization: Conducting rigorous reviews by subject matter experts, ensuring linguistic accuracy, cultural sensitivity, and addressing all feedback prior to launch.

- Program Launch and Learner Recruitment: Implementing targeted marketing campaigns through various channels to reach diverse populations, with special focus on underrepresented groups in cybersecurity.

- Training Delivery and Continuous Support: Facilitating the learning experience through live Q&A sessions, discussion forums, and providing personalized support to maintain learner engagement.

- Assessment and Certification: Evaluating learner performance through exams, providing detailed feedback, and awarding certificates to successful graduates.

- Impact Analysis and Project Management: Measuring the program’s effectiveness through quantitative and qualitative data collection while ensuring efficient coordination, risk management, and sustainability planning throughout the project lifecycle.

Client Name:

Electrolux – Gas Cookers Factory, Egypt

Service Category:

Tooling Development

Project date:

2022 (Program of three repeated projects)

Short Description of Project

Project Objective:

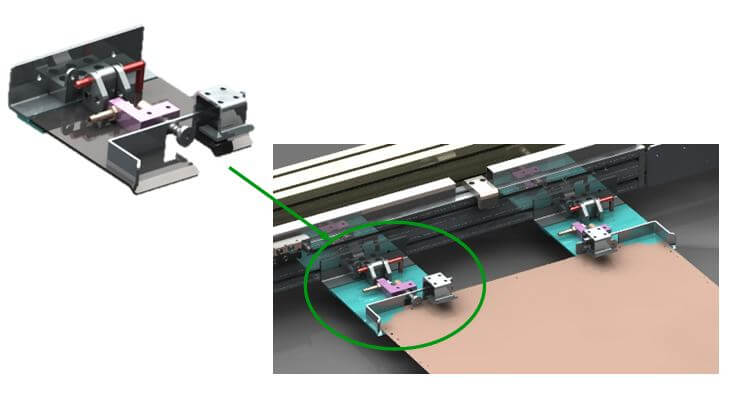

Redesign, fabrication and delivery of modified gripper for press-automation transfer arm

Project Activities:

- Reverse engineering and redesign of the gripers based on newest operational requirements.

- Manage the fabrication process of all tooling in scope.

- Finalize the project by delivery of the equipment based on factory acceptance testing.

Client Name:

Electrolux – Gas Cookers Factory, Egypt

Service Category:

Tooling Development

Project date:

2015 (Program of three repeated projects)

Short Description of Project

Project Objective:

Redesign, fabrication and delivery of modified gripper for press-automation transfer arm

Project Activities:

- Reverse engineering and redesign of the gripers based on newest operational requirements.

- Manage the fabrication process of all tooling in scope.

- Finalize the project by delivery of the equipment based on factory acceptance testing.

Client Name:

Turbine Efficiency, United Kingdom

Service Category:

Engineering Analysis

Project date:

2021

Short Description of Project

Project Objective:

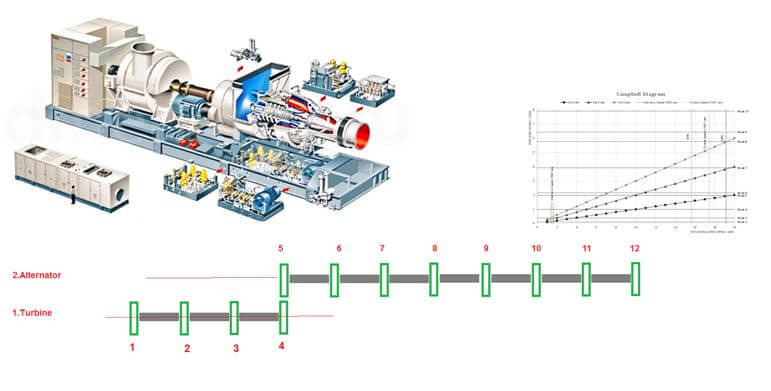

Torsional vibration analysis of modified combined drive train of a Siemens.SGT-100-1S.(S. S. Typhoon) Gas Turbine.

Project Activities:

- According to the API Recommended Practice for Packaged Gas Turbines, a computerized analysis, using commercial software, of the undamped torsional resonances, (critical speeds) of the combined drive train was performed was performed.

- This produced a Campbell Diagram giving plots of critical speeds; possible torsional excitations of one, two and three times per revolution of the drive shafts and resonant points of interference.

- A report of this numerical analysis was performed, with technical conclusion according to the API norms.

Client Name:

Inkonova AB, Sweden

Service Category:

Product Development

Project date:

2023

Short Description of Project

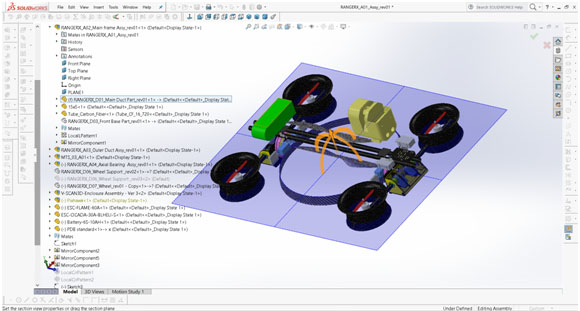

Project Objective:

According to Engineering Services Outsourcing Contact, the primary duties are focused on developing mechanical concepts for drone systems for commercial applications focus on mining and underground industrial sector.

Project Activities:

- Detail design of structural components, electro-mechanical design, payloads mechanical design,

- Flight control and power hardware integration,

- Stress analysis, prototype hardware development, sustaining engineering, and performing design verification testing.

Design work accomplished using CAD tools (SolidWorks), and rapid prototyping techniques (3D printing, etc.).

Client Name:

![]()

Asfour Crystal International, Egypt

Service Category:

Product Development – systems integration

Project Date:

2022-2024 (Program of five integrated sub-projects)

Short Description of Project

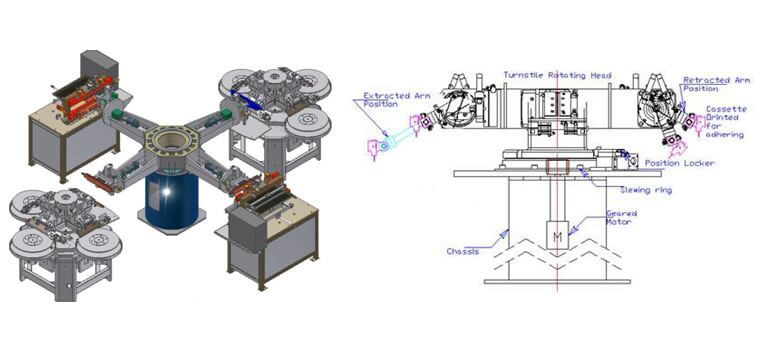

Project Objective:

Develop fully automated loading and unloading of crystal processing machines

Projects Activities:

- Modify the Production cell layout.

- Motion time study and optimization.

- Design the turn style machine for the automatic handling of the clock machine.

- Manufacturing the system parts.

- Assembly and integration.

- Testing and modifications.

- Troubleshooting.

- System Documentations (maintenance and operation manuals).

Client Name:

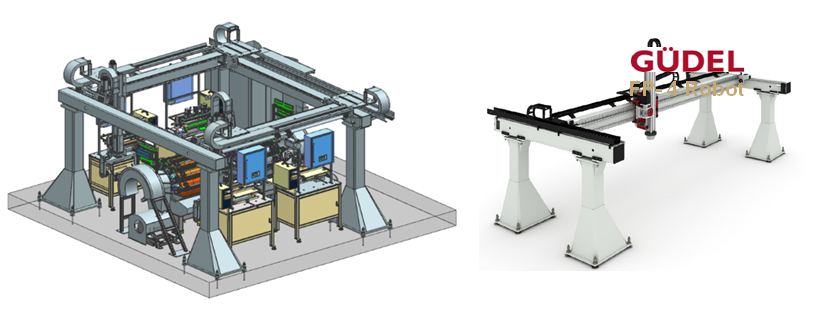

![]()

Asfour Crystal International, Egypt

Service Category:

Product Development – systems integration

Project Date:

2013-2014 (Program of five integrated sub-projects)

Short Description of Project

Project Objective:

Develop fully automated loading and unloading of crystal processing machines

Projects Activities:

- Modify the Production cell layout.

- Motion time study and optimization.

- Redesign and fabrication of grinding, polishing and adhering machines.

- Design and fabrication of novel inverting machine.

- Utilize high dynamic gantry robot with specific requirements from Gödel, Switzerland.

- Testing performed for each machine separately, then integration of all production cells

- Commissioning of the production cell.

Client Name:

Maadi Company for Engineering Industries, Egypt

(Affiliated with the Ministry of Military Production)

Service Category:

Tooling Development

Project Date:

2023-2025 (Program of repeated 28 projects)

Short Description of Project

Project Objective:

Design review and fabrication management of 34 jigs and fixtures.

Project Activities:

- Review and approve the jigs & fixture.

- Mange the fabrication process of all tooling in scope.

Client Name:

ASEC Environmental Protection – ASENPRO, Egypt

Service Category:

Product Development

Project Date:

2022-2024

Project Objective:

Develop, produce and supply of Part with modified engineering characteristics for cost reduction.

Projects Activities:

• Using sample of the original metallic part to get the geometrical characteristics.

• Study the working condition of the part for new material selection to comply with project objective

to be changed from Die casting Aluminum to Fiberglas Reinforced Polyamide (Nylon).

• Develop drawings and analysis documentations of the design and verifications.

• Develop engineering documentations of the production process ( Injection molding process )

• Fabricate the production tooling (Injection Mold )

• Perform production operations and deliver the contracted quantity of the part.